Annual inspections of equipment and systems avoid fines, downtime, and most importantly – catastrophic events

OSHA, ANSI, manufacturers, and common sense all agree: every part of a fall arrest system, including PPE, must be inspected by the user before each use and by a competent person at least once a year, or more often if conditions require. Annual inspections help detect gradual wear that daily users might miss, preventing failures during critical moments.

OSHA fines can be issued due to irregular equipment inspections or missing documentation.

Fallproof can remedy that through our inspection services, including engineering, ensuring industrial and commercial environments less down time and fewer to no fines.

Here are the areas were we can provide inspection services:

ENGINEERING & RECERTIFICATION

Ensuring systems are compliant, certified, and safe for continued use

The most common inspection issues involve:

– Unverified system capacity

– Outdated or missing engineering documentation

– Systems modified without review

– Expired or incomplete certifications

FallProof engineering services address these risks by:

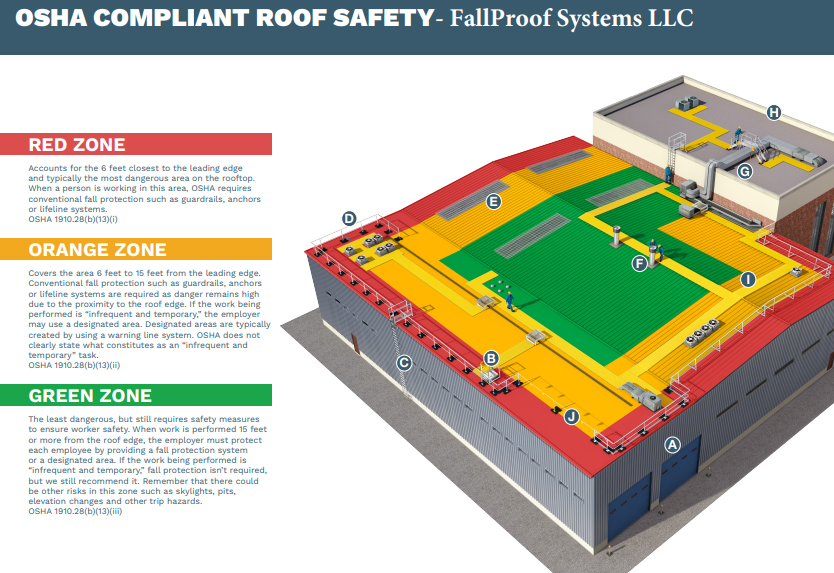

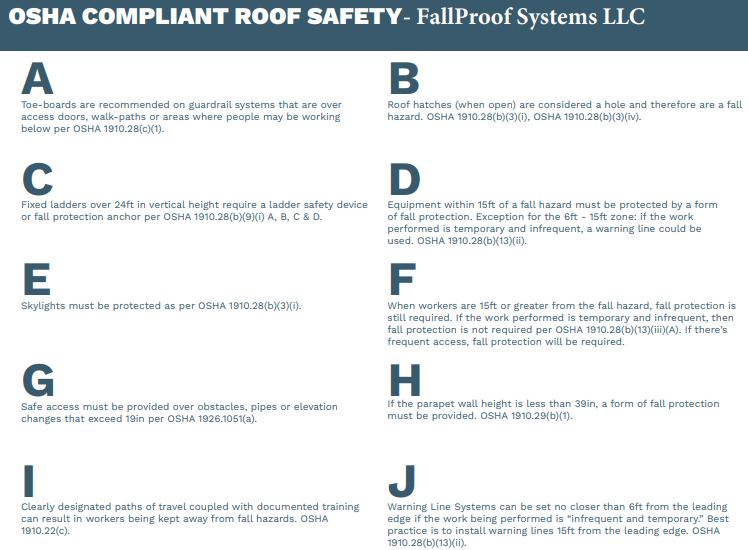

– Evaluating existing fall protection systems against applicable OSHA regulations and ANSI standards

– Confirming system capacity and structural integrity

– Performing load testing when required

– Providing signed and sealed engineering documentation where applicable

FALL PROTECTION SYSTEM INSPECTIONS

Ongoing verification of installed fall protection systems

Fall protection systems require regular inspection to ensure compliance with OSHA requirements and applicable ANSI standards, while maintaining safe working conditions for employees.

FallProof inspects a wide range of systems including:

– Horizontal and vertical lifelines

– Rigid rail and overhead track systems

– Anchors, guardrails, and netting systems

Each inspection includes detailed reporting, identified deficiencies, and clear recommendations for corrective action.

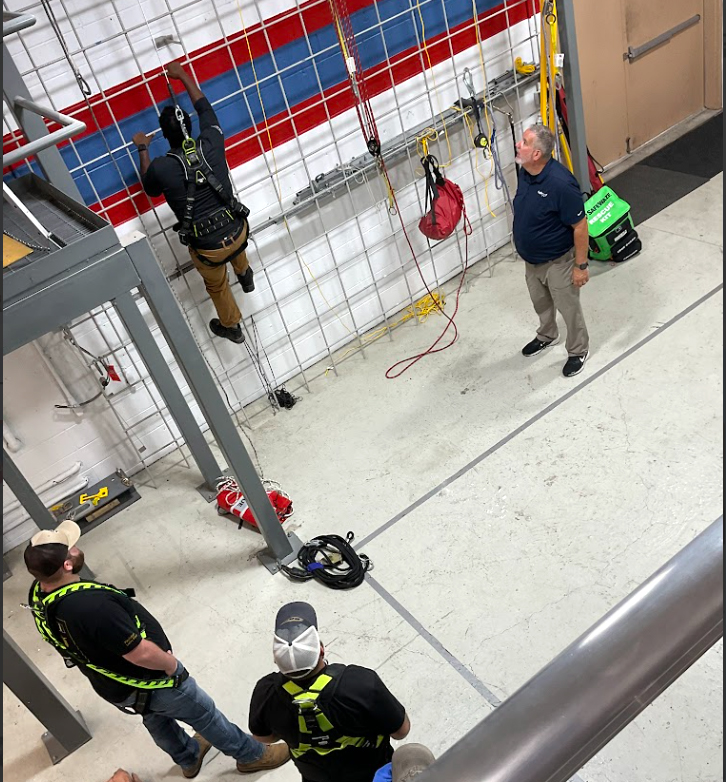

USER EQUIPMENT INSPECTIONS

Protecting workers through proper equipment evaluation

Personal fall protection equipment is critical to worker safety and must be inspected regularly.

Routine inspections help employers meet OSHA requirements for maintaining personal protective equipment in safe, serviceable condition.

FallProof inspects:

– Harnesses, lanyards, and self-retracting lifelines

– Connectors, carabiners, and anchorage devices

– Rescue and specialty equipment

Inspection programs help:

– Remove unsafe equipment from service

– Extend equipment life through early detection

– Maintain proper documentation for audits and compliance

FallProof’s In-The-Cloud Historical Inspection Records Improve Efficiency

We RFID-tag everything we inspect and certify, and we securely store historical inspection records in the cloud. This allows our technicians in the field to quickly pull up a checklist, review notes and pictures from previous visits, document observations and comments for the next year, and issue a certificate that everything is in good working order and can be relied on for the next year. In the event we are not able to issue a certificate, we recommend the equipment be immediately removed from use, and provide an estimate of the cost to repair or replace the failing components. Our database also allows us to immediately provide a snapshot of the inspection status of a customer’s equipment, whether it is located in one building or spread among multiple facilities across the country.

Let us help you save time and money by making scheduled inspections part of your fall protection best practice.

📅 Schedule a Safety Assessment Today »

📞 Or call us at (609)-325-5555