OSHA Fall Protection Standards: Misconceptions can be solved with TRAINING

The Problem: Misunderstanding Fall Protection Rules

Falls remain the leading cause of worker fatalities in construction and general industry. OSHA requires fall protection at elevations of 6 feet in construction and 4 feet in general industry, but many worksites either misunderstand these thresholds or apply them inconsistently. Add to that the confusion between OSHA’s minimum standards and ANSI’s best practice guidelines, and it’s easy for a company to believe they are compliant when in reality their workers are still at risk.

Why These Problems Exist

- OSHA vs. ANSI: OSHA standards are law, but they often lag behind industry advances. ANSI standards are voluntary, but they represent the most current thinking on safety. For example:

- OSHA requires that anchor points support 5,000 pounds per worker, but ANSI clarifies how those anchors should be tested and applied.

- OSHA requires that a worker’s fall arrest system limit free fall to 6 feet, while ANSI outlines stricter maximum arresting forces to reduce injury risk.

- Training Gaps: Equipment alone doesn’t keep workers safe. If a worker doesn’t know how to inspect their harness, calculate fall clearance, or recognize when a system is improperly installed, the protection fails.

- Site Misconceptions: Supervisors often assume that a “competent person” just means someone with experience, when OSHA requires that person to be trained to identify hazards and authorized to correct them.

These gaps create unsafe environments where a single misstep can lead to a catastrophic fall.

The Correct Solution: Training That Translates Standards Into Practice

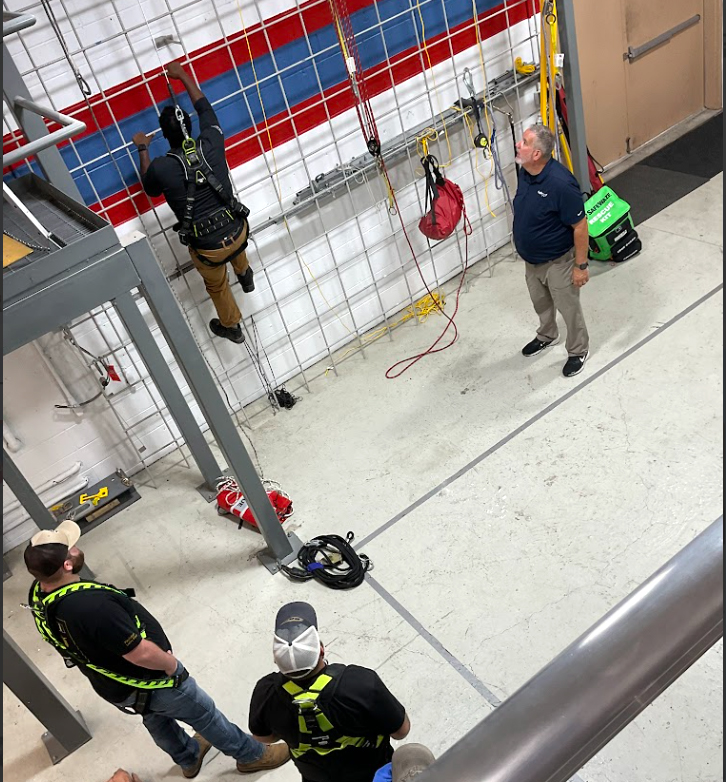

This is where structured, hands-on training becomes non-negotiable. FallProof Systems integrates OSHA and ANSI requirements directly into the following programs:

Fall Protection Competent Person Training

- Teaches supervisors and managers how to recognize fall hazards, evaluate systems, and take corrective action.

- Meets OSHA’s requirement that a competent person be present on job sites.

- Covers both OSHA’s baseline and ANSI’s stricter criteria so leaders can exceed compliance.

Authorized User Training

- Gives workers the practical skills to use personal fall arrest systems, harnesses, lanyards, and SRLs correctly.

- Includes pre-use equipment inspection, anchor point selection and fall clearance calculation.

- Reduces the likelihood of improper use, which is a leading cause of harness failure.

General Awareness Training

- Designed for teams, facility staff, or contractors who need an overview of fall hazards.

- Builds company-wide awareness so safety isn’t just the responsibility of supervisors.

- Creates a stronger safety culture across the organization.

How FallProof Integrates Into the Solution

At FallProof Systems, we do more than design and install equipment. We make sure your workforce understands how OSHA and ANSI standards apply to their daily tasks. Training is offered at our Trenton, NJ training center or directly at your facility for convenience. Every class is led by Ray, who brings years of industry knowledge and the ability to translate dense regulations into practical, actionable steps.

The benefits go beyond compliance:

- Lower risk of OSHA citations and fines.

- Fewer accidents and injuries on the job.

- Increased worker confidence and productivity.

- A stronger reputation as a safety-focused employer.

Don’t let confusion over OSHA and ANSI requirements put your workers at risk. Equip your team with the knowledge and confidence to work safely at height. Contact FallProof Systems today to schedule Competent Person, Authorized User, or General Awareness training.

📞 Let’s get started: (609)-325-5555