Here’s how Rooftop Crossovers provide safety for the worker and maintain the integrity of the roof.

Rooftop crossovers are modular stairs or ramps installed on commercial and industrial roofs to provide safe, designated pathways for workers to navigate over obstacles such as pipes, ducts, equipment, and changes in elevation.

Why Rooftop Crossovers Are Important

Rooftop crossovers are crucial for two primary reasons: ensuring worker safety and protecting the structural integrity of the roof and equipment.

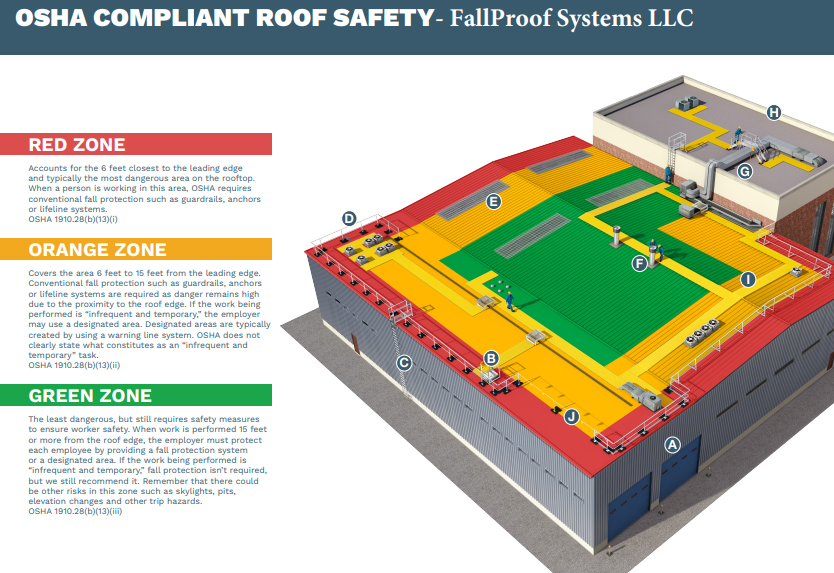

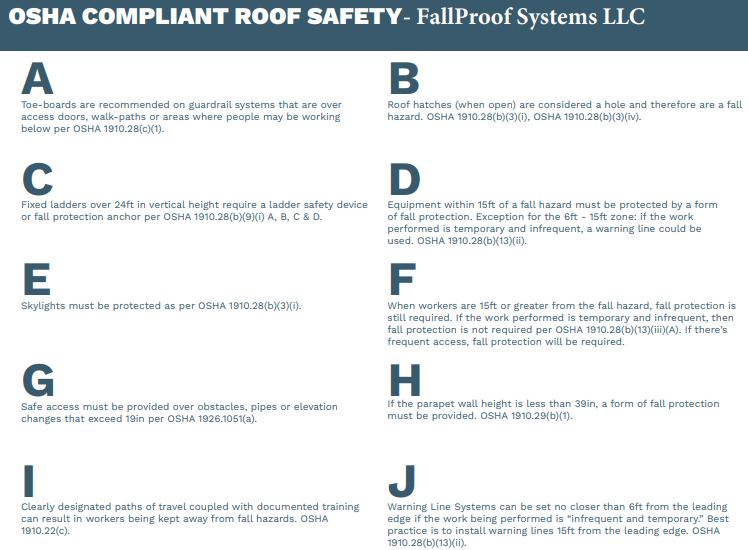

- Enhanced Safety and OSHA Compliance

Roofs are inherently hazardous environments. Crossovers mitigate significant safety risks and help building owners comply with Occupational Safety and Health Administration (OSHA) regulations.

- Prevents Falls and Trips: They provide a stable, anti-slip walking surface with guardrails, eliminating common trip hazards like loose cables, pipes, and sudden elevation changes.

- Eliminates Unsafe Practices: They remove the need for maintenance personnel to use unstable ladders or climb over equipment, which is the leading cause of rooftop falls.

- Meets Regulatory Standards: OSHA and other building codes require permanent, safe access solutions for equipment installed on roofs above certain heights and for crossing obstacles over a specific size. Non-compliance can result in substantial fines and legal liability in case of an accident.

- Protection of Roof Membrane and Equipment

Foot traffic directly on the roof surface can cause significant, premature damage that compromises its ability to waterproof and insulate the building.

- Maintains Roof Integrity: Crossovers provide a non-penetrating system (often using base plates or clamps) that distributes weight evenly and keeps workers off the delicate roof membrane, thus preventing punctures, abrasions, and damage to seams.

- Protects Warranties: Many commercial roof warranties are voided by damage from unmanaged foot traffic or by penetrating the roof membrane during installation, both of which are avoided by using non-penetrating crossover systems.

- Prevents Equipment Damage: By guiding workers over obstacles, crossovers protect expensive equipment like HVAC units, solar panels, and piping from being accidentally stepped on or damaged.

In summary, installing a rooftop crossover is a cost-effective safety solution that protects personnel, preserves valuable building assets, and ensures regulatory compliance for any facility requiring regular rooftop maintenance.

- Basic Requirements

- Load capacity: Stairs must be able to handle a load of five times the anticipated load, with a maximum weight capacity of at least 1,000 pounds.

- Guardrails: Guardrails are required on all open sides and must be at least 42 inches high.

- Handrails: A handrail must be on the open side of the stair system.

- Forces: Guardrails and handrails must be able to withstand at least 200 pounds of pressure from any direction.

- Toeboards: Toeboards are needed if there is a risk of tools or objects falling to a lower level.

- Surface: All surfaces must be smooth to prevent catching on clothing or other items.

Stair dimensions

- Width: Minimum of 22 inches.

- Riser: Maximum of 8 inches high.

- Tread: Minimum of 9.5 inches deep.

Landing requirements

- Dimensions: Must be at least as wide as the stairs and a minimum of 30 inches long in the direction of travel.

- Door swing: If a door swings near the landing, there must be at least 21 inches of clearance from the door swing’s end.

Other considerations

- Clearance: If the step-across distance from the ladder or stairs to the platform exceeds 12 inches, a landing platform is required to reduce the distance.

- Markings: Crossovers, aisles, and passageways must be conspicuously marked

✅ Ready to Uncover the Hidden Risks?

Let us help you turn rooftop hazards into protected zones.

📅 Schedule a Safety Assessment Today »

📞 Or call us at (609)-325-5555