The top 10 most cited OSHA violations are dominated by fall protection & training. We can remedy that.

Again in 2025, the same key categories of Fall Protection dominate the OSHA violation list, underscoring ongoing challenges in maintaining safe work environments. Let’s break down the issues, solutions, and benefits of addressing fall protection violations. Fallproof makes it easy for your company to stay not only compliant, but most importantly free from catastrophe.

Here are the Top 5 sections cited:

1. 1926.503(a)(1): The employer shall provide a training program for each employee who might be exposed to fall hazards.

The program shall enable each employee to recognize the hazards of falling and shall train each employee in the procedures to be followed to minimize these hazards. – 1,216 violations

2. 1926.503(b)(1): The employer shall verify compliance with paragraph (a) of this section by preparing a written certification record. The written certification record shall contain the name or other identity of the employee trained, the date(s) of the training, and the signature of the person who conducted the training or the signature of the employer. If the employer relies on training conducted by another employer or completed prior to the effective date of this section, the certification record shall indicate the date the employer determined the prior training was adequate rather than the date of actual training. – 491

3. 1926.503(a)(2): The employer shall ensure each employee has been trained, as necessary, by a competent person. – 97

4. 1926.503(c)(3): Inadequacies in an affected employee’s knowledge or use of fall protection systems or equipment indicate that the employee has not retained the requisite understanding or skill. – 90

5. 1926.503(c): “Retraining.” When the employer has reason to believe that any affected employee who has already been trained does not have the understanding and skill required by paragraph (a) of this section, the employer shall retrain each such employee. – 11

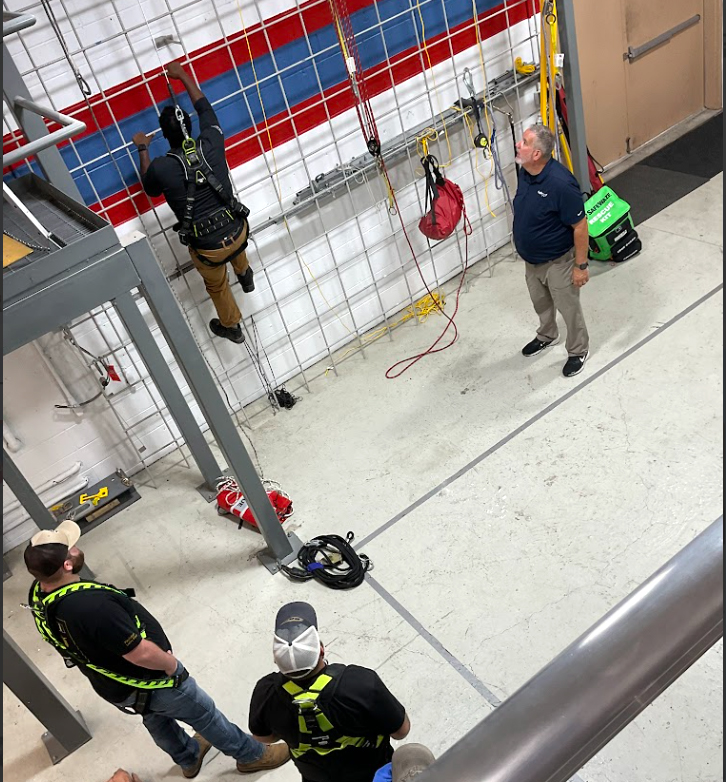

The Fallproof Training Center can help solve these violations

Let’s talk about the differences in the trainings.

Authorized User Training for fall protection is a job-specific program for employees who regularly work in areas where fall hazards exist. The training ensures these workers can identify hazards, use, inspect, and maintain fall protection systems, and follow safety procedures to work safely at heights. The training is essential for anyone performing the actual work at height, and it is often conducted by a competent person. Call for a price to train your team members at your facility or at our Training Facility where they have the freedom of hands on training and not just sit and listen.

Competent Person Training is a course that teaches an individual with the necessary knowledge and authority to identify fall hazards, inspect fall protection systems, and ensure compliance with safety standards. This training is required for designated employees who have the responsibility to correct unsafe conditions and can take prompt corrective measures to protect workers from falls at heights of six feet or more. Call to discuss the pricing and class structures. Availability of open enrollment classes through FallProof.com.

The takeaway:

Staying compliant with OSHA standards benefits companies far beyond avoiding fines. Strong safety programs reduce workplace injuries, which means less downtime and lower costs from accidents. Safe work conditions improve employee morale and retention, fostering a culture where workers feel valued and protected.

These factors combine to support productivity and long-term business success. Compliance also helps companies maintain their reputations, which is essential in competitive industries that demand reliable and safe operations.

📅 Schedule your free fall protection assessment »

📞 Let’s get started: (609)-325-5555